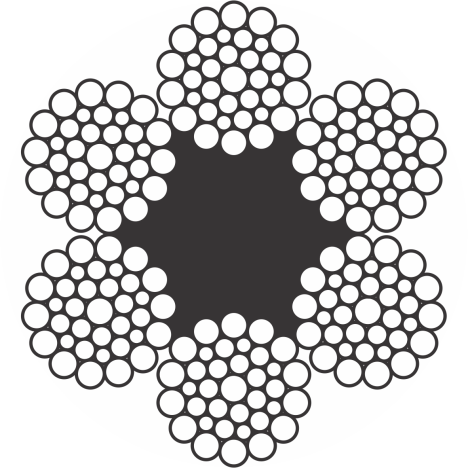

STEEL WIRE ROPE STS 147.2K

- Standart EN 12385-4 35(W)xK7

- Application rotation-resistant ropes, for cranes, mining lifting ropes

More detailed

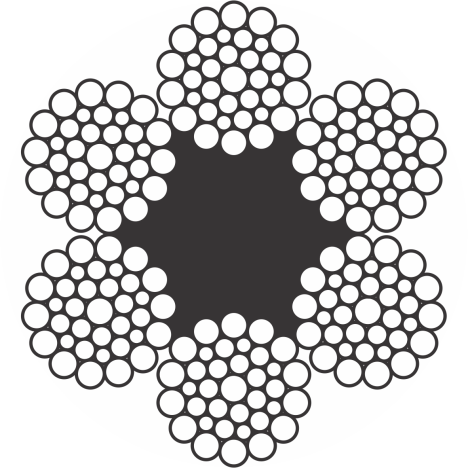

STEEL WIRE ROPE STS 147.2

- Standart EN 12385-4 35(W)x7

- Application rotation-resistant ropes, for cranes, mining lifting ropes

More detailed

STEEL WIRE ROPE STS 1444.A

- Standart TU 14-4-1444-87 execution А

- Construction 6х36(1-7-7+7-14)-FC

- Application ropes for hoisting-transport machines, mining ropes for hoisting plants

More detailed

STEEL WIRE ROPE STS 1444.B

- Standart TU 14-4-1444-87 execution B

- Construction 6х36(1-7-7+7-14)-FC

- Application ropes for hoisting-transport machines, mining ropes for hoisting plants

More detailed

STEEL WIRE ROPE STS 3089

- Standart EN 12385-4 6x6x19W-FC, ISO 2408, GOST 3089

- Construction 6x6х19(1-6-6+6)-FC

- Application multi-purpose lifting ropes

More detailed

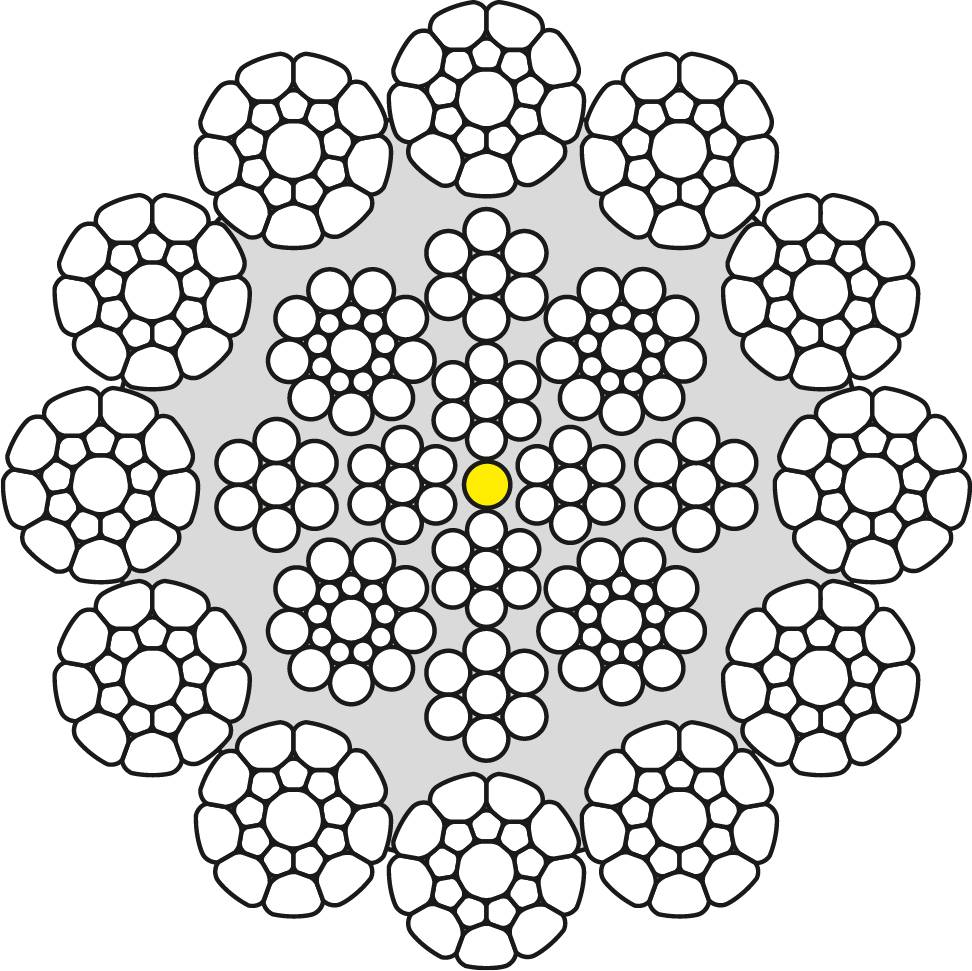

STEEL WIRE ROPE STS 100

- Standart EN 12385-4,6 16хK7-EPIWRC(K), ISO 2408

- Construction 16хK7-EPIWRC(K)

- Application rotation-resistant ropes, for cranes, mining lifting ropes

More detailed

STEEL WIRE ROPE STS 121.2K

- Standart EN 12385-6 12хK36WS-EPIWRC, ISO 2408

- Construction 12хK36(1-7-7+7-14)-EPIWRC

- Application mining lifting ropes for vertical shafts, balance rope

More detailed

STEEL WIRE ROPE STS 121.1

- Standart EN 12385-6 12хK19S-EPIWRC, ISO 2408

- Construction 12хK19(1-9-9)-EPIWRC

- Application mining lifting ropes for vertical shafts

More detailed

STEEL WIRE ROPE STS 121

- Standart EN 12385-6 12х19W-EPIWRC, ISO 2408

- Construction 12х19(1-6-6+6)-EPIWRC

- Application mining lifting ropes for vertical shafts, balance rope

More detailed

Wire rope products of the PJSC “Stalkanat” – are available in wide range of steel wire ropes of various constructions.

Ropes manufactured by PJSC “Stalkanat” are used in various industries – coal, mining, oil and gaz production, metallurgy, transport and agricultural machinery, construction industry, railway transport, energy, marine complex and other.